When you're choosing commercial lighting solutions, it's easy to focus on style and price. But the most important detail for a safe and successful project is that small UL certification mark. This simple seal of approval ensures the fixture has been rigorously tested, protecting your property, your team, and your investment from serious risks.

UL Certification Explained: The Gold Standard for Safety

Underwriters Laboratories, or UL, is an independent global safety science company dedicated to promoting safe living and working environments. For over a century, its mission has been to test products and set safety standards to prevent accidents, injuries, and property damage. UL operates as a neutral third party, meaning its evaluations are unbiased and focused purely on safety and performance.

When a product is described as UL certified lighting, it means that a representative sample of that fixture has undergone rigorous testing by UL engineers to meet nationally recognized safety standards. These tests check for a wide range of potential hazards, including risks of fire, electrical shock, and long-term durability. A product only earns the UL mark after it has successfully passed all of these demanding evaluations.

The UL mark on a product or its packaging is much more than just a sticker; it is your assurance that the fixture was designed and manufactured with safety as a top priority. It shows that the manufacturer has invested in independent testing to ensure their product is reliable and accountable. When you choose UL certified products, you are choosing a proven commitment to safety.

Are You Paying Too Much? The Hidden Costs of Non-Certified Lighting

When specifying commercial lighting solutions, the initial temptation may be to select the lowest-cost fixture to meet a budget. However, choosing non-certified lighting is a classic example of saving pennies now while risking dollars later. This section addresses the tangible business risks associated with fixtures that haven't been vetted by a safety organization like Underwriters Laboratories (UL). The potential for failure, financial loss, and liability significantly outweighs any small, upfront cost savings.

Beyond the Flicker: Hidden Dangers in Plain Sight

Non-certified lighting introduces a spectrum of severe, often hidden, hazards into a commercial environment. These fixtures lack the necessary engineering rigor and independent testing to guarantee safety under regular use.

- Fire Hazard from Overheating: Uncertified lights frequently use substandard components that cannot properly manage the thermal load. For example, a non-certified fixture might lack an adequate heat sink, which is essential for drawing heat away from LED chips or other internal components. When installed in enclosed or insulated ceilings, this poor thermal management can cause the fixture to overheat, melting insulation, damaging adjacent building materials, and ultimately igniting a fire.

- Electrical Shock: Faulty internal wiring, poor strain relief, or inadequate insulation are common flaws in non-certified products. These deficiencies can lead to electrical shorts, exposure to live wires, or a compromised electrical ground, posing a direct and potentially fatal electrical shock risk to maintenance workers or building occupants.

- Premature Component Failure: Without rigorous testing, the long-term reliability of non-certified fixtures is questionable. Component failure, such as LED driver burnout, is common. This leads to spotty illumination, disruptive maintenance, and a loss of the very efficiency the lighting was intended to provide.

Project Killers: How Non-Certified Lights Derail Your Business

The risks of using non-certified ul certified lighting extend beyond physical safety; they can completely derail a construction project's timeline and budget.

- "Red-Tagging" and Costly Rework: Virtually all municipal building codes and electrical standards mandate the use of independently certified electrical products. During the final electrical inspection, an inspector can refuse to approve the work—a process commonly known as "red-tagging"—if they find non-certified lighting installed. This forces the contractor or owner to replace every non-compliant fixture. The resulting labor and material costs for this rework, coupled with significant delays to project completion, can obliterate any initial savings.

- Voiding Insurance and Increased Liability: A major, and often overlooked, business risk involves liability. In the event of an incident like a fire or electrical injury caused by a lighting fixture, insurance companies will immediately investigate the product's certification status. If it's determined that non-certified products were used in violation of safety codes, the business insurance policy—including property, casualty, or liability coverage—may be deemed void. The property owner or specifying firm would then face full financial responsibility for damages, lawsuits, and regulatory fines, placing the entire business at risk.

What to Look for When Choosing a Great Commercial Lighting Partner

Finding a manufacturer is about more than just buying a light fixture; it's about establishing a relationship that protects your project's safety, timeline, and budget. While UL certification is the non-negotiable baseline for safety, it's just the first step. The best commercial lighting manufacturers build a culture of quality, support, and reliability that lasts long after the products are installed.

Here are the key questions to ask to see if a supplier is truly a long-term partner.

Do They Build Safety in From the Start?

As we've covered, top-tier manufacturers don't just test a product at the end; they integrate UL standards into their design and production process from day one. This proactive approach to safety is a powerful indicator of the company's commitment to quality and accountability.

How Do They Handle Custom Certification?

If your project requires custom lighting solutions, this question is critical. Ask them directly: "What is your process for getting a custom fixture UL certified?" A vague answer is a red flag. A reliable partner will have a clear, confident process, whether it's managing in-house testing or coordinating a UL Field Evaluation for on-site approval.

Do They Stand Behind Their Products?

A strong warranty is your best insurance against long-term costs. A manufacturer that is confident in its component quality (like drivers, chips, and heat sinks) will offer a comprehensive warranty, often 5 years or more. This isn't just a piece of paper; it's a financial guarantee that they trust their product to perform, saving you significant maintenance and replacement costs down the line.

What Other Certifications Do They Have?

For a commercial project, safety (UL) is one half of the coin; operational cost is the other. Ask if their products are also certified by DesignLights Consortium (DLC) or ENERGY STAR. These certifications independently verify a product's energy efficiency and performance claims, which is essential for calculating your return on investment (ROI) and qualifying your project for valuable energy rebates.

Will They Be There for Technical Support?

What happens when your installer has a complex question on-site, or a fixture doesn't perform as expected? A great partner provides accessible, knowledgeable technical support. You're not just buying a product; you're gaining access to their expertise. This support can be invaluable for solving problems quickly and keeping your project on track.

Can They Meet Your Project's Timeline and Scale?

A partner's flexibility can make or break your project. Ask about their typical production lead times to ensure they can align with your construction schedule. Furthermore, for specialty areas or smaller projects, look for suppliers offering no moq lighting. This option, also known as lighting no minimum order, gives you the freedom to buy the exact certified fixtures you need without being forced into a large, expensive bulk purchase.

Do All Lights Get the Same UL Certification?

UL certification isn't just one single stamp. A light designed for a dry office has to pass very different tests than a light meant for a wet bathroom. The standards are highly specific to the product's type and, just as importantly, where it's intended to be used. This ensures the fixture is safe for its specific environment.

Let's look at what this means for two common types of lighting.

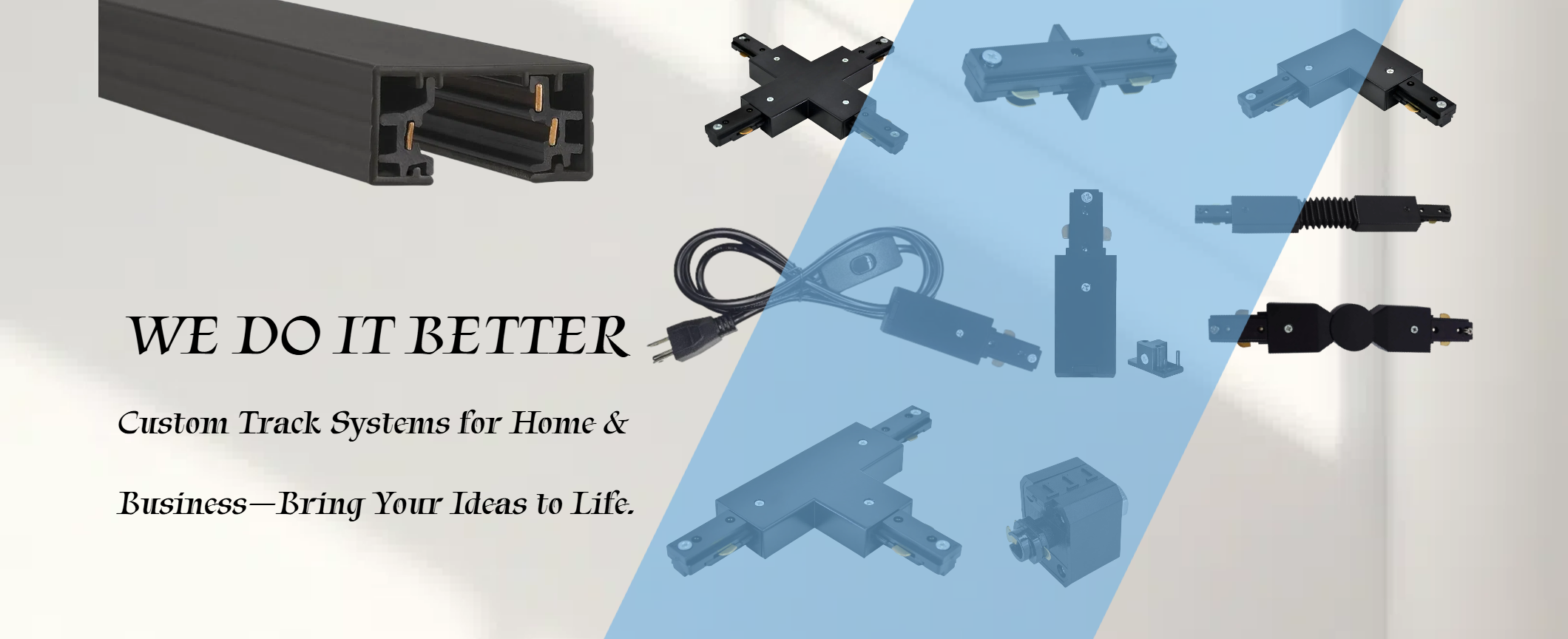

Check the Entire Track System

Track lighting is a popular, flexible choice, but it’s a system, not just a single product. For custom track lighting to be compliant, the track, the power feed, and the fixture heads must all be certified to work together. You can't just buy a certified track from one brand and add unlisted fixture heads from another and assume it's safe. Mixing and matching components that aren't listed as compatible can void the safety rating and create a serious hazard.

Look for Location Ratings on Wall Sconces

When it comes to custom wall sconces, safety testing focuses heavily on heat. A poorly designed fixture can get dangerously hot, posing a fire risk to nearby materials like wallpaper or wood paneling. This is also where you must check the location rating. A sconce marked "UL Damp Location" is built to handle the moisture in a bathroom. A fixture for an outdoor patio or a wash-down area must be rated "UL Wet Location" to prevent short-circuiting and ensure it's safe and code-compliant.

Why Professionals Mandate UL Certification

For experienced architects, designers, and electricians, ul certified lighting isn't an optional "upgrade"—it's a foundational requirement. Professionals know that their reputation, profitability, and even their license are on the line with every project. They understand that a non-certified fixture isn't a "value" item; it's an unvetted liability.

For Architects and Designers: Specification Is Liability

For the design professional, every item on the spec sheet is a direct reflection of their professional judgment and due diligence.

- Code and Liability: Specifying ul certified lighting is the first line of defense in ensuring a design is code-compliant. If a non-certified driver in a custom-built wall sconce overheats and ignites the surrounding material, the liability investigation traces directly back to the specification sheet. This is a direct risk to the firm's E&O (Errors and Omissions) insurance and the designer's professional license.

- Client Protection: A core duty is to protect the client's investment. A non-certified fixture that causes a fire or electrical fault can lead to catastrophic property damage, voiding the client's property insurance and opening the door to devastating lawsuits.

For Contractors and Electricians: Jobsite Reality and Profitability

For installers, the consequences of non-certified products are immediate and costly. Quality lighting for electricians and lighting for contractors is about safety, efficiency, and reliability.

- Passing Inspections (The First Time): A failed electrical inspection is a project killer. An inspector red-tagging 100 non-certified high-bays in a warehouse doesn't just mean a delay. It means the contractor has to pay the labor to remove all 100 fixtures, patch the ceiling, source and pay for compliant replacements, and re-install everything—all while the project schedule and labor budget are destroyed.

- On-Site Safety: This is a physical, personal risk. A certified fixture has been tested to ensure its wiring is properly insulated, grounded, and secured with strain relief. A non-certified fixture might have a live wire pull loose from its terminal block during installation, creating a direct and serious shock hazard for the installer.

- Eliminating Callbacks: A callback to fix a single failed fixture can wipe out the profit on an entire room. Driving back to a site, setting up a ladder or lift, and spending an hour to replace a faulty driver in a high-lobby pendant isn't just an inconvenience—it's unbilled labor that comes directly out of the contractor's pocket. Using ul certified lighting is the best insurance against that loss.

Your Questions Answered: UL Certification for Commercial Lighting

Q1: How can I quickly verify a product's UL certification online?

The most reliable method is to use the UL Product iQ™ database. This is UL's free, official online directory. You can search using the UL file number (often found on the product's UL mark), the model number, or the manufacturer's name to confirm its certification status and the specific standards it has met.

Q2: Is UL certification a one-time approval, or is it an ongoing process for manufacturers?

It is an ongoing process, not a one-time event. To maintain their certification, commercial lighting manufacturers must participate in UL's Follow-Up Services. This program includes regular, unannounced factory inspections by UL representatives to ensure that the products continue to be manufactured with the same materials and processes as the original sample that passed testing.

Q3: What's the practical difference between "UL Listed" and "UL Recognized"?

This is a critical distinction for installers and specifiers:

- UL Listed: This mark is for complete, standalone products (e.g., a wall sconce, a track fixture, a driver-on-board high-bay). It means the end-product has been tested and is safe for installation in the field.

- UL Recognized: This mark is for components within a larger product (e.g., an LED driver, a switch, or an internal power supply). It signifies the component is safe for factory installation inside a complete UL Listed product, but it is not a complete, field-installable item itself.

Q4: My project requires a completely unique, custom fixture. Can it still be UL certified?

Yes. For one-of-a-kind custom lighting solutions or very limited production runs, you can use the UL Field Evaluation service. A UL engineer will come directly to the installation site (or the fabrication shop) to inspect the unique fixture for compliance with national safety standards. If it passes, it will receive a UL Field Evaluated Product Mark, which is accepted by electrical inspectors.

Make UL Certification Your Standard for Lighting Quality

The UL mark is your assurance that a product meets rigorous national safety standards. Choosing ul certified lighting protects your investment, your people, and your project's timeline from the expensive consequences of non-compliance. As you source your commercial lighting solutions, treat certification as a key indicator of a manufacturer's quality. Insist on it with every supplier and commercial lighting manufacturer you work with.