Most commercial lighting manufacturers operate on bulk orders that make sense for big developers but create real problems for contractors and electricians working project-by-project.

When you need 15 fixtures for a boutique renovation or a handful of custom track lighting for a restaurant remodel, minimum order requirements of 200+ units just don't work. Lighting no minimum order suppliers solve this problem by offering quality products in the exact quantities your projects demand.

What Are Minimum Order Requirements in Lighting?

When sourcing commercial and custom lighting fixtures, most manufacturers require minimum order quantities (MOQs)—typically between 100 to 1,000 units per product style. However, some suppliers offer flexible ordering that allows contractors and electricians to purchase project-specific quantities without bulk commitments.

These flexible-quantity suppliers let you order exactly what each job requires—whether that's 5 fixtures or 500—without forcing you to purchase hundreds of units to meet production minimums. For project-based contractors, this means ordering 25 custom track lights for a restaurant or 12 pendant fixtures for an office renovation becomes financially viable.

How Traditional Minimum Order Quantities Work

Most commercial lighting manufacturers operate with substantial minimum requirements that make sense for their production economics but create challenges for contractors working on varied, smaller-scale projects.

Typical Minimum Order Quantities:

Most commercial lighting manufacturers set minimum order quantities between 100 to 1,000 units per product style. Here's what you'll typically encounter:

- Standard fixtures: 100-200 pieces minimum

- Custom lighting solutions: 300-500 pieces minimum Specialized architectural lighting: 1,000+ pieces minimumIf you need custom track lighting in a specific finish, you're often looking at ordering several hundred units just to get started—regardless of your actual project requirements.

Why Manufacturers Set These Minimums:

Manufacturers aren't trying to make your life harder—they're managing real production costs. Every time they run a new order, they face:

- Setup costs: Configuring machinery, preparing materials, and allocating factory time

- Testing requirements: For UL certified lighting, each batch needs certification and quality testing

-

Raw material minimums: Their own suppliers require bulk purchases of components Labor allocation: Workers need to be scheduled and trained for specific production runsWhen a factory produces 500 units instead of 50, they spread these fixed costs across more products. That's why bulk orders cost less per unit—the setup costs get divided among more fixtures.

4 Common Challenges With High Minimum Order Requirements

High minimum order requirements are not only difficult for electricians and contractors working on a variety of projects, but they can also significantly restrict the kind of contracts you can bid on and the way you conduct business.

1. Your Cash Gets Locked in Inventory

You are looking at an upfront investment of $25,500 before you have even begun the installation process, when a manufacturer demands that you order 300 units at a cost of $85 each. Payroll, insurance, car fees, and other overheads make it impractical for most small to mid-sized contractors to commit that much capital to inventory for a particular project type.

You are effectively using your operating capital to finance the manufacturer's manufacturing run, even if you end up using all 300 fixtures across several assignments. Marketing, recruiting more staff, or just keeping a solid cash reserve for slower months could all be done with that money.

2. Risk of Storing Hundreds of Fixtures

Let's say you commit to ordering those 300 fixtures. Where do you put them?

- Warehouse rental: $500-2,000+ per month depending on your location

- Insurance: Additional coverage for stored inventory

- Organization systems: Shelving, bins, and tracking systems

- Risk of damage: Climate control needs, potential for shipping damage or theft Many contractors don't have dedicated warehouse space, which means fixtures end up in garages, storage units, or taking up valuable shop space. Custom lighting solutions can be particularly bulky, and specialized finishes require careful storage to prevent scratches or tarnishing.

3. Getting Stuck With Excess Inventory

Here's a scenario that happens too often: You win a bid for a boutique hotel that needs 85 custom wall sconces in brushed brass. The manufacturer's MOQ is 200 units. You order 200, use 85, and now you're stuck with 115 fixtures in a very specific style and finish that may or may not work for future projects.

If design trends shift or you don't land similar projects in the next year, those fixtures become obsolete inventory. You can try selling them at a discount, but you'll likely take a loss. The "savings" from bulk pricing evaporate when you can't move the excess inventory.

4. You Can't Test New Products First

When you can't order samples or small test quantities, you're forced to either:

- Commit to hundreds of units of an untested product

- Stick with the same fixtures you've always used, even if better options exist This puts you at a competitive disadvantage. If a client asks about newer, more energy-efficient custom track lighting options, you can't easily test them without a major financial commitment. Innovation becomes risky instead of manageable.

Benefits of Flexible Order Quantities

Suppliers who accept low minimum orders or flexible quantities offer contractors a different approach—one that aligns with how project-based businesses actually operate.

Lower Upfront Costs and Better Cash Flow

Flexible order quantities dramatically reduce the capital required to start and complete projects. Instead of tying up tens of thousands of dollars in inventory, you invest only what each specific job requires.

Financial impact:

- Ordering 30 fixtures at $85 each = $2,550 upfront investment

- Ordering 300 fixtures at $85 each = $25,500 upfront investment

- Capital preserved: $22,950 that stays available for other business needs Ongoing Costs Eliminated:

Expense Category Monthly Cost Annual Cost Notes Warehouse rental

$500-2,000

$6,000-24,000

Varies by location and space size

Inventory insurance

$100-400

$1,200-4,800

Based on inventory value

Storage systems

One-time: $500-2,000

N/A

Shelving, bins, organization

Risk of obsolescence

Variable

$5,000-15,000

Average loss on unsold specialty fixtures

Order Exactly What Each Project Needs

With flexible minimums, you can bid on diverse projects without forcing your ordering to fit artificial quantity requirements. This precision ordering eliminates waste and improves your project margins.

Real Project Examples:

| Project Type | Fixtures Needed | Traditional MOQ | Excess Inventory | Capital Wasted |

|---|---|---|---|---|

|

Restaurant renovation |

22 pendant lights |

100 units |

78 units |

$6,630 |

|

Office retrofit |

47 linear fixtures |

100 units |

53 units |

$4,505 |

|

Retail buildout |

15 track heads |

50 units |

35 units |

$2,975 |

|

Residential project |

8 custom sconces |

25 units |

17 units |

$1,445 |

Business Impact:

- Bid competitively on smaller projects (under 50 fixtures) that bulk-only suppliers can't serve

- No pressure to upsell clients on unnecessary fixtures to meet supplier minimums

- Each project maintains its intended margin without excess inventory costs

- Eliminate the practice of "borrowing" from bulk stock and hoping to use it later

Test Before You Commit to Large Orders

Small sample orders let you verify product quality, test installation procedures, and get client approval before committing to full project quantities—reducing risk at every stage.

Sample Ordering Strategy:

| Stage | Sample Quantity | Purpose | Typical Cost |

|---|---|---|---|

|

Initial evaluation |

2-3 units |

Inspect quality, finish, specifications |

$200-300 |

|

Client presentation |

1-2 units |

On-site approval in actual conditions |

$100-200 |

|

Installation testing |

1-2 units |

Verify mounting, wiring, compatibility |

$100-200 |

|

Total sample investment |

5-7 units |

Complete verification |

$400-700 |

Quality Verification Checklist:

| Verification Category | What You Can Check With Samples | Why It Matters |

|---|---|---|

|

Physical quality |

Finish consistency, welds, component fit |

Prevents callbacks and reputation damage |

|

Light performance |

Output, color temperature, beam angle |

Ensures client satisfaction with lighting effect |

|

Spatial compatibility |

Scale, proportions, visual weight |

Confirms fixture works in actual space |

|

Technical specs |

UL certification, dimming, voltage |

Avoids code violations and reinstallation |

|

Installation ease |

Mounting system, wiring access |

Estimates labor accurately for bidding |

Risk Comparison:

If a supplier's quality doesn't meet expectations or the fixture isn't right for the space, you've risked $500-800 instead of $5,000-25,000. This approach protects your reputation with clients and gives you confidence in every installation you complete.

When exploring options for tailored lighting, consider the benefits of custom-engineered solutions that can streamline your projects and enhance your designs.

Types of Custom Lighting Available Without MOQs

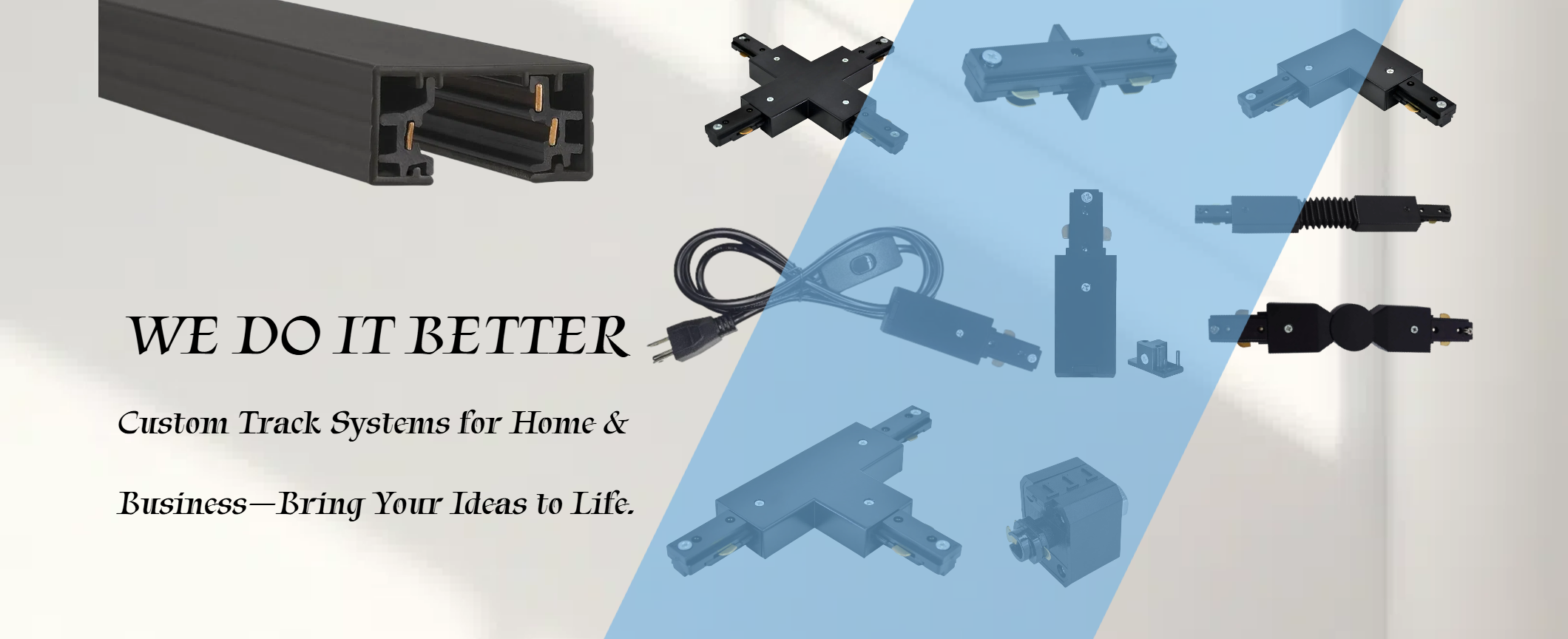

Custom Track Lighting

Track lighting systems let you customize finishes (black, white, brass, nickel), number of light heads, beam angles, and track lengths. Common applications: retail stores, galleries, kitchens, and restaurants where directional lighting matters.

What works well:

- Adjustable after installation if client needs change

- Versatile across different project types

- Clients can see exactly how it highlights products or artwork

Trade-offs:

- Expect to pay 15-30% more per fixture compared to bulk pricing

- Custom finishes add 2-3 weeks to production time

Custom Wall Sconces and Decorative Fixtures

Wall sconces offer the most design flexibility—customize arm lengths, shade shapes, finishes, and mounting styles to match each project's aesthetic. Best for hotels, restaurants, homes, and building exteriors where design is a priority.

What works well:

- Meets specific design requirements without compromise

- Available in quantities that match single-project needs (10-30 units)

- Easy to show physical samples for client approval

Trade-offs:

- Higher per-unit cost than bulk orders

- Highly specific designs may not suit future projects, limiting reuse

Commercial and Industrial Lighting

Functional lighting for commercial applications: high-bay lights, linear LED panels, emergency lighting, and task lighting. Warehouses, offices, and industrial facilities typically need 20-75 fixtures per project.

What works well:

- Order exact quantities each facility requires

- UL certified options available in small batches

- Works well for retrofit projects with specific code requirements

Trade-offs:

- Smaller price breaks compared to bulk purchasing

- Specialty items (explosion-proof, cold-storage rated) may still require 25-50 piece minimums

How to Find Reliable No MOQ Lighting Suppliers

Finding suppliers who advertise low minimums is easy—finding ones who consistently deliver quality products on time with solid support requires careful vetting.

Verified Safety Certifications

Always verify UL listing numbers on the official UL Product iQ database. For commercial projects, this isn't optional.

- UL listing number matches the specific product model

- ETL, DLC, or Energy Star certifications for relevant applications

- Supplier provides documentation immediately without hesitation

Consistent Quality Across All Order Sizes

Request 2-3 samples before your first actual order and inspect carefully

- Finish quality and uniformity meet specifications

- Wiring integrity and strain relief are properly executed

- Components fit together with no gaps or misalignment

- Weight and material quality match specifications

- Contacted other contractors about their small-order experience

Realistic Lead Times You Can Plan Around

Get lead times in writing and track whether suppliers hit their windows consistently

- Supplier provides specific lead times in writing

- Lead times align with reasonable industry standards

- Standard products: 2-4 weeks

- Custom finishes: 4-6 weeks

-

Complex custom work: 6-8 weeks 🚩 Red Flag

Vague answers like "as soon as possible" or patterns of missed deadlines will derail your project schedules.

Responsive Customer Service

Test communication before placing your first order with a technical question

- Response time within 24 hours (professional standard)

- Technical competence in answering questions

- Positive attitude toward small orders (no deprioritization)

Clear Return and Warranty Policies

Get these terms in writing before ordering

- Return window: 30 days standard for unused fixtures

- Restocking fees disclosed (15-25% typical, waived for defects)

- Warranty coverage: Minimum 1-2 years for commercial fixtures

Once you've found 2-3 solid suppliers, treat them like partners, not just vendors:

- Communicate clearly: Send complete specs upfront to avoid back-and-forth delays

- Pay on time: Prompt payment builds goodwill and often unlocks better pricing or priority treatment

- Give feedback: Tell suppliers when they exceed expectations—and when problems need fixing

- Combine orders when you can: Ordering fixtures for multiple projects together can move you into better pricing tiers

-

Give advance notice: More lead time helps suppliers schedule your work, especially during peak seasons Good supplier relationships pay off beyond just pricing. You'll get priority scheduling when you're in a rush, more flexibility on order quantities, and suppliers who'll work with you when problems come up.

Potential Drawbacks and How to Navigate Them

The Trade-Offs You'll Face

No MOQ lighting typically costs 15-30% more per unit than bulk orders. A fixture that's $65 in quantities of 500 might be $85 when you order 20. Lead times can also stretch longer—4-6 weeks instead of 2-3 weeks for stock items. Very small orders (under 10 units) may have limited customization, so that unique brass finish might require ordering at least 15 pieces.

Getting Better Value From No MOQ Suppliers

Build relationships with 2-3 reliable suppliers. Regular customers often get better pricing and priority scheduling. When you have multiple small projects, combine orders to hit better price breaks—ordering 50 fixtures across three jobs beats three separate 15-unit orders.

Use a hybrid approach: order lighting no minimum order for one-off projects and custom work, but negotiate bulk pricing with your go-to supplier for fixtures you use repeatedly. This balances flexibility with cost efficiency.

How to Make Flexible Quantity Orders Work for Your Business

Success with flexible quantity ordering comes down to precision and planning. Follow these steps to avoid common pitfalls and ensure smooth project execution.

Lock Down Your Specifications Before Ordering

Create a detailed specification sheet that includes:

- Exact dimensions (height, width, depth)

- Finish and color (with manufacturer's finish code if available)

- Voltage and wattage requirements

- Mounting type and hardware needs

- Color temperature (2700K, 3000K, 4000K, etc.)

- Dimming compatibility requirements Review this spec sheet with your client and get written approval before submitting the order. On a 20-unit order, one wrong finish means project delays and difficult conversations you don't need.

Add Buffer Time to Quoted Lead Times

Schedule your project for 7-8 weeks if a supplier estimates 4-6 weeks. When manufacturers are operating huge production batches, small orders may not always receive the same attention.

Inform clients about reasonable deadlines right away:

- "Standard fixtures typically arrive in 4-5 weeks"

- "Custom finishes add 2-3 weeks to production time"

- "I'll update you if fixtures arrive early" This keeps client expectations in line with reality and avoids rushing to justify delays.

Is No MOQ Lighting Right for Your Business? A Decision Framework

Not every contractor needs no MOQ lighting suppliers, and not every project justifies bulk ordering. Here's how to figure out what works for your business.

You'll Benefit Most From No MOQ Suppliers If...

- Your projects vary significantly Doing a restaurant one month, residential remodel the next, and small office after that? Each project needs different fixtures, styles, and quantities. Diverse project portfolios benefit from suppliers who adapt to whatever comes next.

- You're a smaller operation without warehouse space Running your business from a shop or garage makes storing 300 fixtures unrealistic. Small contractors and electricians benefit from ordering project-by-project rather than maintaining large inventories.

- You want to test new products or suppliers Testing custom lighting you haven't used before? Order samples, see how clients respond, and scale up if it works—all without financial risk or bulk commitments.

Traditional Bulk Ordering Makes More Sense When...

- You're doing high-volume repeat work Installing identical fixtures across 20 franchise locations or multiple apartment units? When you know exactly what you need in substantial quantities, bulk pricing saves 20-30% per fixture.

- You have major commercial projects lined up Large installations—200-room hotels, 50,000-square-foot retail spaces—need volume that justifies bulk orders. Per-unit savings at this scale offset storage and upfront costs.

- You have proper warehouse infrastructure Already have climate-controlled storage, inventory management systems, and insurance? Bulk ordering makes sense. Use your existing overhead to capture better pricing.

Use Both Strategically

Most successful contractors don't pick one approach exclusively. Instead, they:

- Keep reliable staples in bulk: If you install the same custom track lighting system in 60% of your retail projects, buy that in bulk. You know you'll use it.

- Order custom work as needed: For unique custom wall sconces or project-specific fixtures, use no MOQ suppliers. Don't tie up capital in inventory you might use once.

- Test with small orders, scale with bulk: Try new products in quantities of 10-20 units. Once you know quality and demand, negotiate bulk pricing for future orders. The key is matching your ordering strategy to each project type rather than forcing every job into the same purchasing model.

Frequently Asked Questions

Q1: How can I check the qualifications of a lighting supplier?

On the UL Product iQ database, look up the UL listing number. Visit the websites for ETL, DLC, or Energy Star certifications. Reputable vendors offer documents right away. It's a warning sign if they falter or are unable to provide substantiated figures.

Q2: Do large orders for lighting items have higher quality than MOQ lighting products?

No. Order size has no bearing on quality; the manufacturer does. For 10 or 1,000 units, reputable suppliers uphold the same standards. Before placing an order, always ask for samples and confirm certifications—some lower-tier suppliers sometimes take shortcuts on modest quantities.

Q3: How much more costly is lighting that doesn't require a minimum order?

15% to 30% more per unit, on average. For small purchases, a fixture that costs $65 in bulk could cost $80-85. Although the cost per piece is higher, you save money on storage and don't have to pay for extra inventory.

Q4: Can I get UL-certified lights without fulfilling minimum orders?

Indeed. UL-certified lighting is available in modest quantities from numerous no-MOQ lighting providers. The product itself, not the order size, is subject to UL certification. Particularly for commercial projects, always confirm the UL listing number on the official UL database.

Q5: Are there no custom lighting solutions available from MOQ suppliers?

Yes, but only to a certain extent. When 10–25 units are ordered, the majority of providers alter finishes, dimensions, and configurations. A minimum of 25–50 pieces may still be needed for very specialized adaptations. Before completing your design, inquire about the flexibility of custom lighting options.

Q6: Are lighting providers with no minimum order quantity appropriate for commercial projects?

Indeed. They are ideal for renovations, small-to-medium-sized commercial spaces, and projects requiring a variety of fixture types in low quantities. This flexibility helps electricians and contractors who work on commercial projects with lighting. Bulk pricing may still be justified for large installations with more than 500 identical units.

Making Custom Lighting Work for Your Contracting Business

For contractors, lighting doesn't have to mean settling for generic fixtures or placing excessive orders. You can purchase UL-certified lighting, bespoke wall sconces, and custom track lighting in the exact amounts your project requires from lighting providers with no minimum order quantity. Order samples, check the quality, and establish a rapport with suppliers who handle 20-unit orders with the same seriousness as 200-unit orders.