For a unique project, sourcing the right fixtures can feel like searching for something that isn't manufactured yet. That's because standard lighting often falls short—it looks out of place or can't handle the space's performance demands. To get a result that truly shines, use custom lighting. It gives you total control over style, size, and function, so your finished project perfectly reflects what you envisioned.

The "One-Size-Fits-None" Problem with Big-Box Lighting

Lighting for a hypothetical "average" space is what big-box stores carry, but your projects are rarely average. It is nearly always necessary to make concessions that detract from the final appearance and functionality when attempting to install one of those mass-produced fixtures in a distinctive, tailored location.

So, why can't standard, off-the-shelf lighting deliver for high-end projects?

- Aesthetic Clashes: Even though a stock fixture's finish, color, or design may be similar, it might be difficult to locate the ideal match. A flawless design might be tainted by subtle mismatches, such as a color temperature that destroys your palette or a brass finish that conflicts with your hardware.

- Inadequate Lighting: Standard sizes and heights are accommodated by generic fixtures. You'll frequently encounter bothersome issues like deep, dark shadows, insufficient light where you need it, or glare that makes it difficult to see if your space is taller, longer, or has an odd layout.

- Incorrect Scale: The optical balance is frequently upset by standard sizes. A fixture might ruin the visual harmony by seeming overly big and intimidating in a small room or too little and lost in a large entryway.

- Functional Limitations: You're simply stuck with the features the manufacturer decided on. Need a precise beam angle to highlight artwork? Want to fine-tune the exact color temperature for a specific mood? With generic lights, you can't adjust the settings to meet the exact needs of your environment.

Problem 1: When Your Lighting Clashes with Your Vision

A common issue arises when your design calls for a specific finish, like a deep bronze, but the fixture you want is only available in a shiny brass. Similarly, your project may require a specific warm light (2700K) to enhance the wood tones, yet the only option that fits the space produces a harsh, cool blue light (4000K). This frustrating scenario is a common headache where a standard light fixture functions correctly but actively works against your design's identity. These small clashes—a slightly wrong color, an incorrect scale, or a mismatched color temperature—can disrupt the entire feel of a carefully curated space, making it look unprofessional or incomplete.

You can avoid these aesthetic compromises because custom lighting puts you back in control, allowing you to create fixtures that perfectly align with your design goals.

Here's how custom lighting solutions restore your design integrity:

- Aesthetic Control: You can specify the exact finish, material, and scale to match your project's aesthetic down to the last detail.

- Atmosphere: You get to dictate the precise color temperature and lumen output to create the desired mood and atmosphere.

- Unique Elements: You can design unique pieces, such as custom wall sconces, that act as both functional lighting and signature architectural elements.

Problem 2: Battling Awkward Shadows and Annoying Glare

You've finally located the perfect linear fixture for the lobby of a boutique property, but you only need 20, and you have to order at least 500. Professionals working on unique assignments are forced by this significant obstacle to either overspend, maintain unnecessary inventory, or accept a less-than-ideal alternative. Large manufacturers' high minimum order quantities (MOQs) are designed for volume rather than the unique requirements of lighting for electricians and contractors working on custom projects.

A custom lighting solution allows you to place light exactly where it’s needed for optimal functionality and visual appeal.

Here's how a custom approach solves illumination issues:

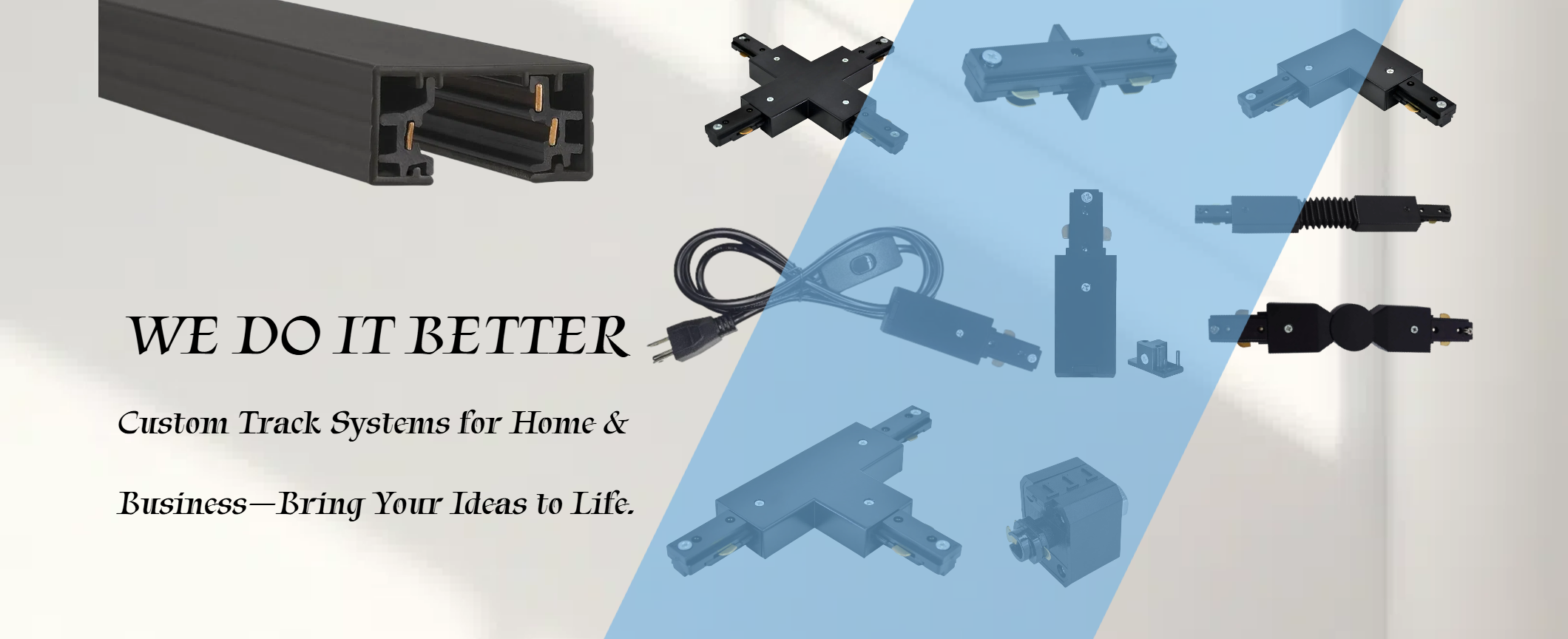

- You can design custom track lighting systems to any length, perfectly fitting the exact dimensions of your space, no matter how long or uniquely shaped.

- You can position adjustable heads to eliminate dark corners and provide focused, task-specific illumination.

- You can perfectly highlight key features, such as artwork in a gallery or countertops in a kitchen, without causing distracting glare.

Problem 3: "Minimum Order of 500? But I Only Need 10!"

You've finally found the ideal linear fixture for a boutique project's lobby, only to discover you have to order a minimum of 500 units when you only need 20. This major roadblock forces professionals working on unique jobs to either blow the budget, store unwanted inventory, or settle for a less-than-ideal substitute. High minimum order quantities (MOQs) from large manufacturers are built for volume, not for the specialized needs of lighting for contractors and lighting for electricians on custom projects.

The right partners offer a more flexible approach, freeing you from the constraints of high minimum order quantities.

Here’s how flexible manufacturing is a game-changer for your business:

- You can work with specialized commercial lighting manufacturers that cater to professional needs and offer no moq lighting.

- This flexibility, making lighting no minimum order a reality, allows you to access specialized fixtures without a large, unnecessary upfront investment.

- You can bid accurately on jobs of any scale, ensuring you get the exact pieces you need without being forced to buy hundreds of extra units.

Problem 4: The Fear of Failed Inspections and Costly Callbacks

There is nothing more frustrating than finishing a project and then having an electrical inspection fail because an unlisted light fixture was used. For instance, even though a unique chandelier you saw online might look amazing, an inspector could stop the project altogether if it hasn't been tested to fulfill safety regulations. A cheap, unlisted fixture is more likely to fail early—the transformer burns out or the internal wiring frays—requiring you to deal with an expensive and annoying callback, in addition to the original danger of costly delays and a tarnished reputation.

You can eliminate this risk for your projects and clients by prioritizing safety and compliance from the start.

Here is why you should always specify UL certified lighting:

- Guaranteed Compliance: Specifying UL certified lighting is the most reliable way to guarantee that your fixtures meet strict safety and quality standards required for passing inspections.

- Verified Safety: The UL mark confirms the product has passed rigorous, independent testing against fire and electrical hazards.

- Professional Confidence: This certification provides essential peace of mind for you and your client while demonstrating a commitment to professional-grade, reliable work.

Problem 5: When the Utility Bill Undoes All Your Savings

The sticker price of a light fixture is only the beginning of its true cost. Consider a store that installs dozens of inexpensive, generic track heads. Even if the original purchase was cheap, the energy expenses would increase every month if those fixtures use inefficient parts or take up too much space. Over time, these high operational costs can completely offset whatever savings you made on the first purchase, turning an ostensibly alluring deal into a long-term financial burden for the client.

An efficient bespoke lighting solution saves a lot of money over the fixture's lifetime since it is built for maximum efficiency from the specification stage.

Here's how a customized strategy increases productivity and return on investment:

- Cut Down on Waste: A personalized plan makes sure you use only the light you need, which stops you from wasting energy by overpowering a room.

- Focus the Light: This smart approach often gives you better, more targeted light with fewer fixtures and lower overall power use compared to a generic system.

- Save Money Long-Term: The client quickly sees a return on investment (ROI) because their operating expenses stay low over time.

Is Custom Lighting Worth It? Absolutely.

Ultimately, choosing a custom lighting solution is a strategic investment in the quality and success of your project. It moves beyond the compromises of standard fixtures to provide a product that perfectly aligns with your aesthetic vision, functional requirements, and safety standards. From solving tricky installation challenges to ensuring long-term efficiency, a custom approach delivers a superior result that both you and your client can be proud of.

Frequently Asked Questions About Custom Lighting

Q1: Why is UL certification important for lights?

Lighting that is UL approved has undergone extensive testing by an impartial laboratory to guarantee that it is safe and won't present any fire or electrical risks. Passing building inspections, upholding your professional reputation, and providing your client with assurances on quality and safety all depend on this certification.

Q2: Can you make specific types of lights, like custom wall sconces?

Of course. Making unique things is a big advantage of bespoke work. Anything from a massive chandelier to specialized custom track lighting or distinctive custom wall sconces that precisely complement your design concept can be designed and constructed by us.

Q3: How long does it typically take to manufacture custom lighting?

The complexity of the fixture, the materials needed, and the manufacturer's current production schedule all affect the lead time for custom lighting solutions, which typically ranges from 6 to 12 weeks. Manufacturers of commercial lighting should always be consulted early in the project design process.

Q4: Can any type of custom track lighting or fixture incorporate LED components?

In reality, high-efficiency LED technology is incorporated into practically every custom lighting fixture created by modern commercial lighting manufacturers. This allows precise control over color temperature, beam angle, and lumens for specific projects.